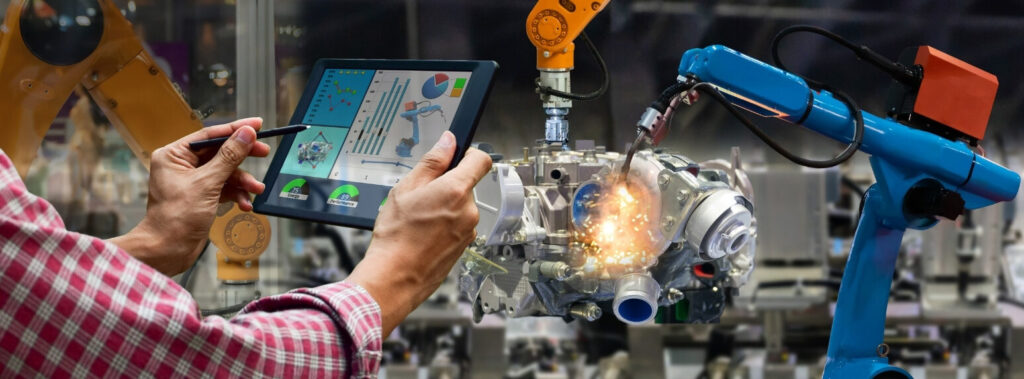

Revolutionizing Efficiency with Kertz Industrial Robotics

Kertz Industrial Robotics offers cutting-edge automation solutions designed to enhance productivity, precision, and operational efficiency. Tailored to meet the demands of modern industries, Kertz robotics seamlessly integrates advanced technologies with robust engineering for optimal performance. Delivers unparalleled accuracy, minimizing errors and ensuring consistent results in production processes.

Innovative Robotics Solutions for Every Sector

Reliable Support, Worldwide Reach, and Unmatched Warranty

01

Service Center Excellence

Kertz Global’s service centers worldwide provide fast, reliable, and expert repairs, ensuring your tools stay in optimal condition with minimal downtime.

02

Global Distribution Network

With a broad network of international distributors across many countries, Kertz ensures easy access to products, parts, and support, no matter where you are.

03

Comprehensive Warranty

Kertz offers an extensive warranty on all products, giving you peace of mind with long-term protection and support for your tools.

Elevating Industry Standards with Kertz Robotics Technology

Customizable for Diverse Applications

Kertz industrial robots are designed to adapt seamlessly to various industries, from manufacturing and automotive to healthcare and logistics.

Precision and Reliability

Equipped with advanced sensors and control systems, Kertz robotics ensures unparalleled accuracy and consistent performance even in demanding environments.

Efficiency-Driven Automation

Our robotics solutions significantly reduce operational costs by streamlining workflows and optimizing productivity across all industry sectors.

Easy Integration and Scalability

Kertz robots are engineered for hassle-free integration into existing systems, with scalable solutions that grow alongside your business needs.

Explore Kertz’s Full Range of Power Tools Products

Robotic Arms

Robotic arms are versatile robotic systems designed for various tasks such as pick-and-place, assembly, and material handling.

Automated Assembly Systems

Automated assembly systems use robotic technology to perform assembly tasks such as inserting parts, screwing, or welding.

Material Handling Robots

Material handling robots are designed to automate the movement, storage, and retrieval of materials.

Welding Robots

Welding robots are specialized robotic systems used for welding applications, ensuring precise and consistent welds with high repeatability.

Inspection Robots

Inspection robots are used to monitor and assess the quality of products during and after production.

Painting & Coating Robots

Painting and coating robots automate the application of paint and coatings to surfaces, ensuring uniform coverage and high-quality finishes.

Packaging Robots

Packaging robots are automated systems used to package products efficiently and consistently. These robots are designed to handle tasks like filling, sealing, labeling, and palletizing.

AI & Control Systems

AI & control systems are the brains behind robotic operations. These systems use artificial intelligence to optimize robot performance, enhance precision, and enable autonomous decision-making.